|

|

|

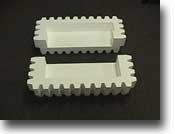

Custom Molded Packaging

Expanded Polystyrene (EPS) is often the packaging material selected for critical packaging applications by virtually every industry needing product protection. EPS is comprised of 90 percent air. The shock absorbing properties and other qualities of EPS foam, combined with its low-cost, high insulating properties, custom moldability and ease of processing make it a popular packaging material.

EPS Advantages:

- Excellent protection and cushioning

- Completely contains the product

- Low abrasion

- Reduces packaging inventories

- Lightweight - reduces shipping costs

- Ease of assembly increases production

- Moisture does not weaken EPS

- Thermal protection for the product

- EPS contains no CFCs, HCFCs or HFCs

- Chemically inert

- EPS is a recyclable material

- Waste to Energy safe

|

|

|

Custom Molded Packaging Products

One of the best features of Expanded Polystyrene Foam is its "moldability". CushPack capitalizes on this feature to provide shock-absorbing packaging that is unique to your application. By shaping the material in specially-designed molds, we can incorporate a precision fit with proven packaging techniques to attain the highest level of protection. Savings are gained through less product damage from shipping and handling.

CushPack Custom Molded EPS delivers:

- Highest quality and best price through state of the art equipment,

- Lower part costs, with best value for high volume

- Exceptional protection and presentation for your product

| |

|

Applications:

|

Coolers and containers for perishables

|

.jpg) |

Cushioning of products for retail, wholesale and business to business OEM

|

|

Complete Encapsulation for bracing and blocking

|

|

|

|

|

|