|

|

|

|

|

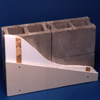

EPS is a unique product that can be manufactured in a wide range of densities and strengths. Most commonly EPS is supplied in a density range from 0.9-2.4 lbs/ft3. The performance properties of EPS in this density range are covered by industry standard ASTM C578. However, some applications require higher strength than covered by ASTM C578.

R-Control EPS can be manufactured to custom high strength performance levels for application subjected to high load conditions. Examples of high strength EPS properties are shown below:

|

|

|

|

|

| High Density EPS Properties1 |

40 PSI |

50 PSI |

60 PSI |

| ASTM C578 Type |

XIV |

- |

- |

| Compressive strength @10% def., min. |

psi

(kPa) |

40

(256) |

50

(345) |

60

(414) |

| Density, min. |

lb/ft 3

(kg/m3) |

2.4

(38.4) |

2.7

(43.2) |

3.0

(48.0) |

Design Thermal Resistance

per 1.0 in. thickness |

40ºF |

ºF•ft2•h/Btu

(ºC•m2/W) |

4.76

(0.84) |

4.76

(0.84) |

4.76

(0.84) |

| 75ºF |

ºF•ft2•h/Btu

(ºC•m2/W) |

4.35

(0.77) |

4.35

(0.77) |

4.35

(0.77) |

Thermal Resistance,min.,

per 1.0 in. thickness |

40ºF |

ºF•ft2•h/Btu

(ºC•m2/W) |

4.60

(0.81) |

4.60

(0.81) |

4.60

(0.81) |

| 75ºF |

ºF•ft2•h/Btu

(ºC•m2/W) |

4.20

(0.74) |

4.20

(0.74) |

4.20

(0.74) |

| Flexural strength, min. |

psi

(kPa) |

60

(414) |

70

(483) |

80

(552) |

Water Vapor Permeance of 1.0 in. thickness,

max., perm |

2.5 |

2.5 |

2.5 |

Water Absorption by total immersion,

max., volume % |

2.0 |

2.0 |

2.0 |

| Oxygen Index min., volume % |

24.0 |

24.0 |

24.0 |

1 When test in accordance with ASTM C578 Test Methods.

|

Download a PDF file of our 40 PSI EPS Brochure.

Download a PDF file of our EPS Product Testing Chart.

|

|

|

|